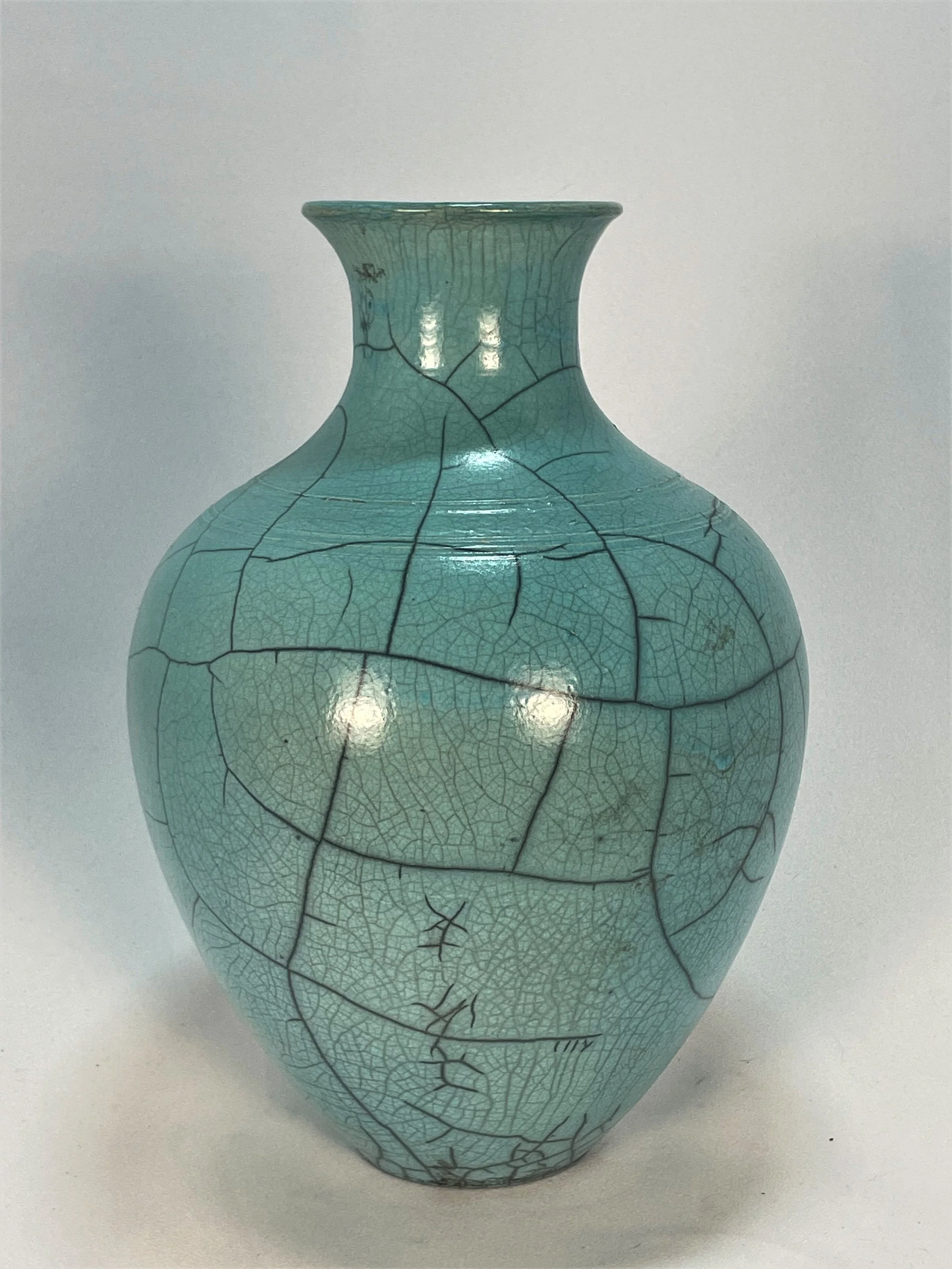

Color & Crackle Raku

In this section of Raku pieces, you will find pieces in which the intent was primarily to produce beautiful colored pieces or pieces that distinctly exhibit Raku crackle response on the surface.

I have grouped Color and Crackle together because both are cooler temperature Raku processes. Glazes like blues and greens have copper in the glaze. In describing the Raku process, I’ve mentioned that “reduction” means exposing the piece to smoke. I accomplish this by putting the hot Raku pottery into a can with a combustible material - newspaper will do - that will burn when in contact with the hot piece. If the piece is hotter when placed in the can and there is more burnable material, there will be more reduction, and metallic effects will predominate from the glaze. If the piece is cooler when placed in the reduction can, the results are more colorful and generally without the metallic lusters. Simply put, if I want to produce non-metallic colors, I expose the raku to the smoke at a lower temperature.

To produce the crackle effect, I pull the piece from the kiln and allow it to cool for a short period before placing it into the combustion chamber. I actually listen for the sound of the glaze cracking. The glaze layer cools quicker than the clay body, so the glaze actually cracks. After placing the pottery into the can, the newspaper catches fire. Closing the lid produces smoke that permeates the glaze cracks, yielding Raku's well-known crackle style.

Examples of the major Color & Crackle forms appear above. Visit the the Shop now to see all Color & Crackle and other styles of Raku